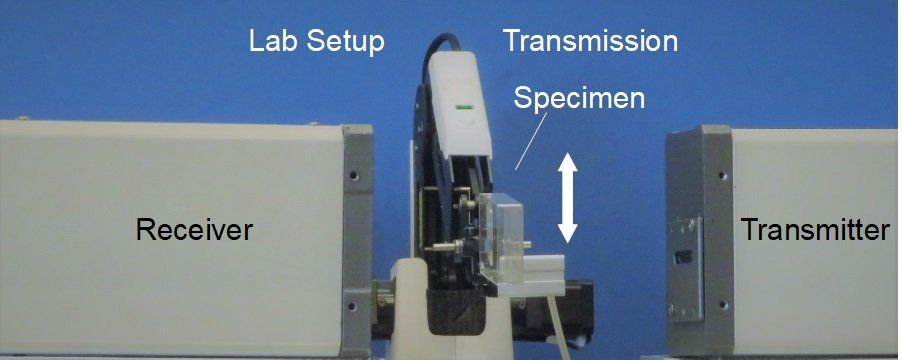

Dual channel transmission inspection

The TSXXX-2k imaging laser scanners consist of a transmitter unit and a receiver unit. They can be used either for dual channel defect and dimensional inspection of transparent test specimens or for inspection of reflectivity of flat surfaces. These inspections differ only in the arrangement of the test object and scanner components as well as the parameterization. In principle, they can be combined if necessary (e.g. with partially reflective surfaces). Defects and anomalies in the transparency, gloss or refectance profile are displayed in brightfield. With the dark field channel, extremely fine defects can be detected in transmission at the same time - with a very high depth of focus. For example, hair can be reliably detected in a depth range of up to 300 mm.

Transmission inspection

Reflection setup

- Development, control and optimization of production processes

- Quality control (in goods issue or goods receipt)

- Transparent (transmission > 10%) clear or colored articles with low refractive powers (flat glass, bar glass, windscreens) also with very large depth expansion (e.g. 300 mm for windscreens)

- Plan, shiny and reflective surfaces

- Imaging telecentric laser scanners

- Evaluation of transmission, gloss or reflectance profiles shown

- The additional inspection in the dark field with a second inspection channel of the scanner allows the detection of extremely fine defects

The scanners provide line scans at their image interface (just like line scan cameras). The following sizes can be determined from the images:

- Anomalies in the transmission or reflectance / gloss profiles (by comparison with recordings of good samples)

- Sizes and accumulations of the defects or anomalies

- Extremely fine defects (<laser beam width)

- Dimensions

Depending on the scanner type down to < 10 µm

Line scan with a length depending on the scanner type from 25 mm to basically not limited. Scanners with an inspection range of 1400 mm have already been achieved with modules with overlapping scan lines.

3R

- Transmitter unit (emits the laser beam)

- Receiver unit

- 24V power supply

- Extremely large depth of field (compared to cameras)

- robust against object displacement

- little effort for adjustment

- Image interface (GiG-E or CameraLink)

- RS-232 interface for parameter setting

OPOS Scanner Player (OSP) for acquiring images and configuring the scanners. A complete evaluation software (Purity) with production line interface is available from our partner Fraunhofer IOSB.

Image samples

Defects in laminated glass panes (point defect, fracture, imprint, fluff)

Send us your samples for a first free test or let us convince you with a device demonstration in your house!

We would also be glad to adapt the sensors to your application or develop new functions for you.

Patents

- M. Hartrumpf, "Laserscanner-Meßsystem"; DE19806288A1

- M. Hartrumpf, "LASER SCANNER MEASUREMENT SYSTEM"; EP1056987A1

- M. Hartrumpf, "Laser Scanner Measurement System"; US6858836B1